-

Bâti d'alliage d'aluminium

-

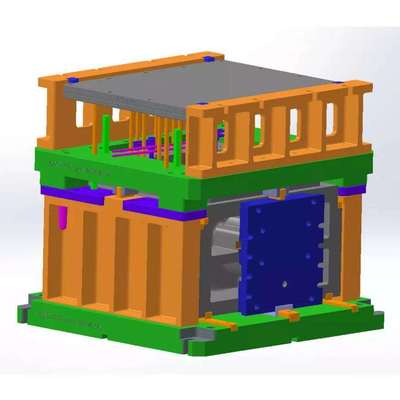

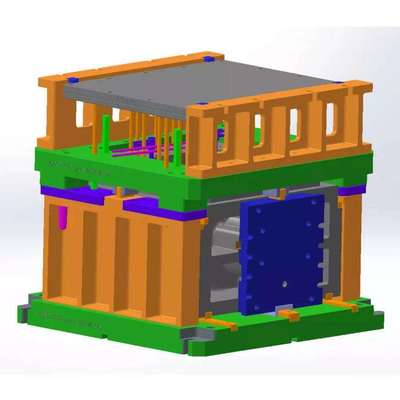

La pression lingotière de moulage mécanique sous pression

-

moules en métal

-

Aluminium meurent moule

-

Moule de mousse d'ENV

-

Moule perdu de mousse

-

Lingotière de moulage au sable

-

aluminium de moulage en moule permanent

-

Die Gravity aluminium coulée

-

Meurent l'outillage de fonte d'aluminium

-

Moule de pièces d'auto

-

Moule multi cavité

-

Moule de culasse

-

moule de haute précision

-

Service d'impression 3d rapide

-

Greg HenkMerci pour votre bonne hospitalité. Votre société est très professionnelle, nous aura la coopération gentille dans un avenir proche.

Greg HenkMerci pour votre bonne hospitalité. Votre société est très professionnelle, nous aura la coopération gentille dans un avenir proche. -

Lionel LoboBonne société avec le service gentil et la réputation de haute qualité et élevée. Un de notre fournisseur digne de confiance, des marchandises sont livrés à temps et le paquet gentil.

Lionel LoboBonne société avec le service gentil et la réputation de haute qualité et élevée. Un de notre fournisseur digne de confiance, des marchandises sont livrés à temps et le paquet gentil.

Low Pressure Aluminum Molding Permanent Mold Die Casting Mould Factory

Contactez-moi pour des échantillons gratuits et des coupons.

WhatsApp:0086 18588475571

Le WECHAT: 0086 18588475571

Skype est là.: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Nom de produit | bâti permanent de moule | Démoulier | Automatique |

|---|---|---|---|

| Utilisant la dureté | >HRC45 | Mousser la vie | 500 000 à 1 000 000 |

| Couleur métallique | Métal noir | Traitement de surface | Traitement thermique |

| Épaisseur moyenne des parois | > 3 mm | Standard | GB ASTM AISI DIN BS |

| Mettre en évidence | low pressure aluminum molding,permanent mold die casting,aluminum die casting mould |

||

Low Pressure Aluminum Molding Permanent Mold Die Casting Mould Factory

Our accelerated development and manufacturing processes ensure quick delivery of high-quality permanent mold systems without compromising on quality or performance. We understand the importance of time-to-market in today's competitive environment.

Appliaction

- Fast-track product development

- Time-sensitive market entries

- Prototype and pre-production requirements

- Rapid response to market opportunities

- Short-run production needs

Aluminum Die Cast Mould Description

1. Drawing: Provide by customer, or design according as the sample.

2. ODM we have the client's idea or draft first,then our experienced engineer will build the best design and manufacturing technology.finally our sales will supply the verified design and solution to our client for confirming.

3. OEM that means Customer design or samples will be very welcome,we will follow client standard to manufacturing this product 100%.

Just give us your sample, drawing or ideas, our professional sales team and engineer team and our workshop staff can make a actual product you want.

Aluminum Die Cast Mould Proudct Range

|

Product Name

|

Aluminum mould die casting

|

||

|

Size

|

Customized

|

||

|

Color

|

As your requirements

|

||

|

Material

|

Aluminum

|

||

|

Application

|

Auto parts, Light fixture, lamp cover, led light housing, heat sink or any other type of die casting parts

|

||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

We strictly control production process by using computer to monitor 24/7, in order to enhance and stable the production quality. VCU has its own highly qualified QC team equipped with all necessary and state-of-the-art testing equipment to be able to perform 100% inspection in order to ensure the best quality products that will be delivered to all of our customers.

Packaging & Shipping

Our products are all packed in wooden cases to ensure zero damage. If customers have specific requirements for the packaging, we will gladly accommodate. The products will be sent to you on time and we will arrange everything from the initial consultation to the delivery of your chosen port anywhere the world. We can also customize the packing method according to customers' needs. Suitable for seaway transportation.

![]()

Our Advantages

-

Reduced lead times through parallel processing

-

Rapid prototyping capabilities

-

Quick-turnaround modifications and adjustments

-

Efficient commissioning and startup support

-

Comprehensive documentation packages

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.

![]()

Accelerate your project timeline! Inquire about our expedited manufacturing options.