-

Bâti d'alliage d'aluminium

-

La pression lingotière de moulage mécanique sous pression

-

moules en métal

-

Aluminium meurent moule

-

Moule de mousse d'ENV

-

Moule perdu de mousse

-

Lingotière de moulage au sable

-

aluminium de moulage en moule permanent

-

Die Gravity aluminium coulée

-

Meurent l'outillage de fonte d'aluminium

-

Moule de pièces d'auto

-

Moule multi cavité

-

Moule de culasse

-

moule de haute précision

-

Service d'impression 3d rapide

-

Greg HenkMerci pour votre bonne hospitalité. Votre société est très professionnelle, nous aura la coopération gentille dans un avenir proche.

Greg HenkMerci pour votre bonne hospitalité. Votre société est très professionnelle, nous aura la coopération gentille dans un avenir proche. -

Lionel LoboBonne société avec le service gentil et la réputation de haute qualité et élevée. Un de notre fournisseur digne de confiance, des marchandises sont livrés à temps et le paquet gentil.

Lionel LoboBonne société avec le service gentil et la réputation de haute qualité et élevée. Un de notre fournisseur digne de confiance, des marchandises sont livrés à temps et le paquet gentil.

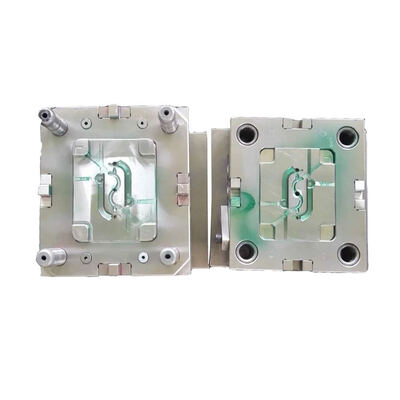

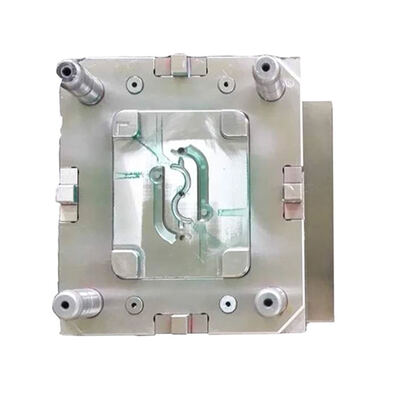

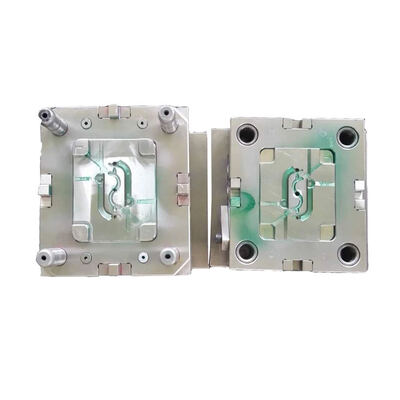

Prix usine du fabricant de moules de moulage par injection plastique Moule d'injection à canaux chauds à 2 cavités, 4 cavités, 8 cavités

| Nom du produit | Moule multi de cavité | Personnalisé | Oui |

|---|---|---|---|

| Démoulier | Automatique | Utilisant la dureté | >HRC45 |

| Durée de vie du moule | 50,000-100,000 tirs | Matériau de moule | Le taux de rendement |

| Traitement de surface | Traitement thermique | Épaisseur moyenne des parois | > 3 mm |

| Gamme de produits | pièces automobiles, lumière, industriel, meubles | Taper | Bâti perdu de mousse |

| Mettre en évidence | Moule de moulage par injection plastique avec garantie,Moule d'injection à canaux chauds multi-empreintes,2 Plâtre à injection en plastique cavité |

||

Fabricant de moules à injection en plastique Prix d'usine 2 cavité 4 cavité 8 cavité moule à injection à coureur chaud

Pour nous, les fabricants de moules, les moules à plusieurs cavités sont l'intersection ultime de l'efficacité, de la précision et du coût.conception scientifique du coureur, une configuration de refroidissement équilibrée, pour sélectionner les procédés de traitement thermique et d'acier les plus appropriés.La réussite de la livraison d'un ensemble stable et efficace de moules à plusieurs cavités à nos clients fournit non seulement un "outil", mais leur permet également de renforcer leur compétitivité sur le marché à long terme.

Si vous avez des produits spécifiques, nous pouvons discuter ensemble de la possibilité, des défis potentiels, et la solution la plus rentable pour réaliser la conception de plusieurs cavités.

Variété de moisissure Proudct

Transport, équipement de machines agricoles, machines de construction, installations de conservation de l'eau, vols spatiaux et aéronautiques, machines chimiques, transport maritime, etc.

Caractéristiques de la moisissure

- Ingénierie avec précision et stabilité dimensionnelle

- Facile à assembler et à démonter;

- Faible entretien

- Une durée de vie plus longue

- Une belle finition.

- Résistance élevée

- Conception robuste

- Nature durable

Description du produit

|

Nom du produit

|

coulée sous pression de moules en aluminium

|

||

|

Taille

|

personnalisé

|

||

|

Couleur

|

Selon vos besoins

|

||

|

Matériel

|

D'aluminium

|

||

|

Application du projet

|

Pièces automobiles, L'éclairage, le couvercle de la lampe, le boîtier de la lampe à LED, le dissipateur de chaleur ou tout autre type de pièces de fonte sous pression

|

||

|

Le service

|

Produit d'origine

|

||

|

Conception du produit

|

Personnalisé selon les dessins ou les échantillons des clients

|

||

Processus de fabrication1- Examiner la conception des pièces, les dessins et les normes de qualité des clients.

2Conception et fabrication de moules et d'outils

3Test de moule et d'outillage et confirmation de l'échantillon

4. La coulée sous pression des pièces brutes

5- Traitement de surface: découpage, dégraissage, polissage, nettoyage, passivation et revêtement de puissance et autres exigences du client

6Utilisation de machines de précision: tour CNC, fraisage, forage, broyage, etc.

7Inspection complète.

8- Je fais mes bagages.

9La livraison.

Les principaux défis et les solutions

- Remplissage constant et maintien de la pression: Même si le canal d'écoulement est équilibré, des différences subtiles dans chaque cavité (polissage, évacuation, refroidissement) peuvent entraîner un remplissage incohérent.Nous utilisons un logiciel d'analyse de flux de moule (tel que Moldflow) pour la simulation, la prédiction des problèmes et l'optimisation avant fabrication.

- Uniformité de refroidissement: la conception de refroidissement des moules à plusieurs cavités est comme une "urbanisation".recevoir une quantité égale de refroidissementDes circuits de refroidissement parallèles et des voies d'eau imitatives sont souvent utilisés pour éviter un refroidissement insuffisant des extrémités causé par une connexion en série.

- La rigidité et la durée de vie des moules: plus de cavités signifient des modèles plus grands et des structures internes plus complexes.et effectuer un traitement thermique spécial (nitridation) à des endroits critiques tels que les intersections des canaux et les petits noyaux pour résister à des contraintes alternatives à long terme et prévenir les fissurations ou l'usure prématurées.

- La gestion des gaz d'échappement doit être soignée: les gaz d'échappement doivent être indépendants et suffisants.avec une profondeur généralement exacte à 0.01-0.03 mm, pour s'assurer que le gaz est évacué et que le plastique ne déborde pas

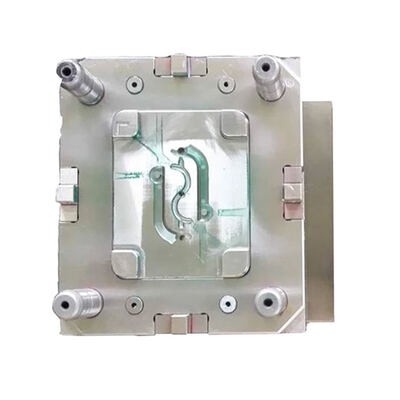

Profil de l'entreprise

Luoyang Liushi Mould Co., Ltd a été créée en 2001, qui est l'unité nationale de définition des normes pour les moules de coulée en mousse perdue.ville de la fleur de pivoine de la ville de LuoyangNous avons 9800 immeubles de bureaux et 22000 ateliers, qui sont bien équipés de recherche, développement, conception, fonderie, usinage, assemblage, traitement de surface et autres équipements.C'est un centre de R&D et de technologie de la municipalité de Luoyang..

![]()

Les techniciens de l'entreprise peuvent fournir sur place l'assemblage des moules guidés, la production d'essai, la réparation gratuite et la technologie complète pour les processus de coulée de mousse perdue selon les exigences du client.Avec la philosophie d'entreprise de "conception soignée"Après des années de développement, nous nous efforçons de fournir des produits et des services satisfaisants pour les clients.notre société est devenue le fournisseur de moules préférés de nombreux fabricants de mousse perdue et le fournisseur exclusif.